Fundilock - Copper cable theft solution for manhole covers

New antitheft system designed to secure any manhole cover and avoid the cable stealing, wire theftor telkom cable theft or copper cable theft, thanks to its geometry and availability of diameters and qualities. It is a patented and innovative product that is being installed in many places including USA and some European countries.

Nuclear power plants such as ASCO, BANDELLOS, Almaraz Cáceres and Trillo in Madrid as well as several city councils rely on Fundilock to tackle the security problem that exists with the theft of caps and what they protect, such as wiring, optic fiber, etc.

We can also manufacture unique wrenches and screws for orders greater than 1000 units, in this way we make sure to have a unique system of wrench and screw, so that the designs are changed by countries and communities.

- Increase security against copper cable theft and telkom cable theft.

- Minimizes the sound of the covers against the frame during the passage of vehicles.

- Prevents unauthorized access to the sewer, increasing security against possible terrorist attacks.

- Avoid accidents to people, animals or cars caused by stolen tops on the road.

- Protects street furniture such as lampposts, benches, etc.

- Protects electrical panels and counters.

- Protect boxes: telecommunications, electricity and sanitation.

- Protects manholes and wells.

| Model | Protection level | Measures | Screw shape |

|---|---|---|---|

| Solid stainless steel AISI--304 | Intense and heavy traffic | 70/100/130/150mm. | Water drop / 3 nipples |

| High impact polypropylene with AIS-304 stainless steel core | Moderate traffic | 70/100/130/150mm. | Water drop / 3 nipples |

| High impact polypropylene with galvanized steel core | Sporadic traffic and sidewalks | 70/100/130/150mm. | Water drop / 3 nipples |

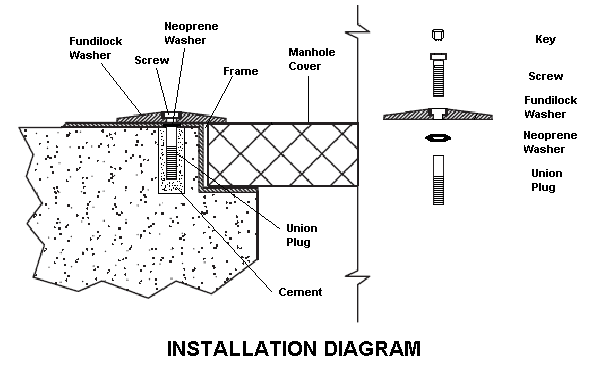

Wet installation

1 - Look for the flattest area next to the frame of the manhole cover to install the Fundilock washer. In case of unevenness it will be necessary to pave with anchoring cement until the outer surface reaches the level of the cover.

1 - Look for the flattest area next to the frame of the manhole cover to install the Fundilock washer. In case of unevenness it will be necessary to pave with anchoring cement until the outer surface reaches the level of the cover.2 - If the cover is hinged, only a Fundilock will be placed on the side of the opening. If it does not have a hinge, 2 to 4 Fundilocks will have to be installed.

3 - Choose the size of the washer (70mm, 100mm, 130mm, 150mm) that allows to protect the manhole cover + frame.

5 - We start by drilling vertically using a 25mm drill bit for concrete, deepening about 100mm depth.

5 - We start by drilling vertically using a 25mm drill bit for concrete, deepening about 100mm depth. 6 - Aspirate the dust produced to leave the hole clean and fill it with bonding material.

6 - Aspirate the dust produced to leave the hole clean and fill it with bonding material. 6.1 – Chemical dowel

6.2 - Composite anchor cartridges

6.2 - Composite anchor cartridges 6.3 - Self-levelling anchoring cement type Sikadur 42

6.3 - Self-levelling anchoring cement type Sikadur 42 7 - We take the special steel union plug piece, 12mm wide x 80mm long, which is composed of a threaded rod welded to a bush. This piece is inserted inside the hole made in step 4, 25mm wide x100mm length, we press it to get it imprisoned until a perfect leveling with the cover that is going to be protected.

7 - We take the special steel union plug piece, 12mm wide x 80mm long, which is composed of a threaded rod welded to a bush. This piece is inserted inside the hole made in step 4, 25mm wide x100mm length, we press it to get it imprisoned until a perfect leveling with the cover that is going to be protected. 8 - Once the bonding material has been sealed with the imprisoned plug piece, place the neoprene washer over the hole to prevent moisture from entering, and on the top of it, the Fundilock washer of the chosen size. Once aligned, we will use the supplied 12mm wide x 100mm long screw, that will be cut to fit perfectly to the upper limit of the Fundilock washer.

8 - Once the bonding material has been sealed with the imprisoned plug piece, place the neoprene washer over the hole to prevent moisture from entering, and on the top of it, the Fundilock washer of the chosen size. Once aligned, we will use the supplied 12mm wide x 100mm long screw, that will be cut to fit perfectly to the upper limit of the Fundilock washer. 9 - We will use the supplied three-pronged wrench, with a recommended tightening torque of 44Nm. The three-pronged wrench is manufactured so that any fixed, monkey wrench or torque wrench can be used.

9 - We will use the supplied three-pronged wrench, with a recommended tightening torque of 44Nm. The three-pronged wrench is manufactured so that any fixed, monkey wrench or torque wrench can be used.Pictures